| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

MOQ : >=1sets

Price : US$66200~US$115000

Payment Terms : T/T

Supply Ability : >300sets/month

Delivery Time : 1-7working days(depand on raw materials stocking)

Packaging Details : export standard wooden case

Brand Name : HongJie

Certification : ISO 14001,ISO 9001,CE,EPA

Place of Origin : Shenzhen,China

Model Number : HJ-ROBr1000GPH

Flow Rate : 1000GPH (customizable )

Conductivity : Grade 1 < 10 μs/cm, Grade 2 < 2 μs/cm;

Fluoride content : ≤ 1.0 mg/L

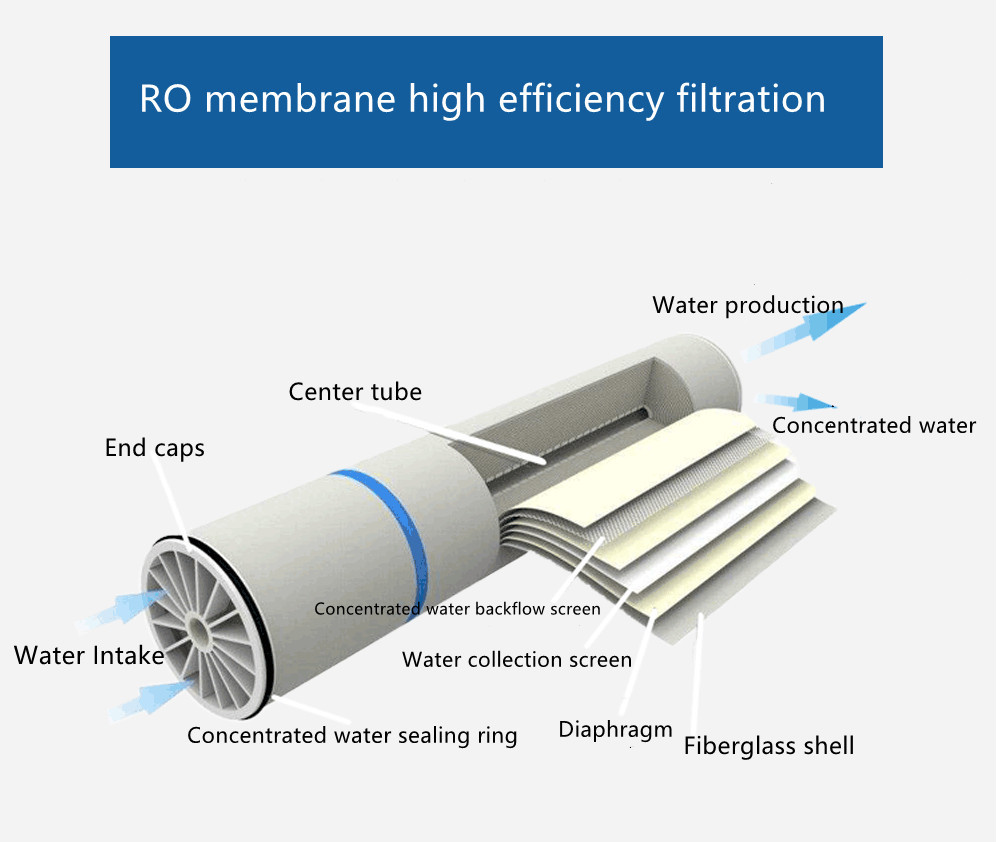

Key Components : RO Membrane Modules

Operation Mode : Full Automatic (PLC-controlled)

Color : 10 times

Turbidity : < 1 NTU

RO recovery rate : > 75%

Microbial control : UV: 40–100 mJ/cm²

Special treatment : Activated alumina: 3–5 mg F⁻/g and above

I.Main Process

Raw water→Activated carbon filtration→Reverse osmosis→ Ion exchange→Sedimentation/Oxidation filtration→UV disinfection→ Membrane filtration→ Boiling→Chemical treatment→Treated water

II.Core Purification Methods

| Activated carbon filtration | A basic step, mainly used to remove chlorine and organic substances. | |||||||

| RO (Reverse Osmosis) system | It can provide high flexibility and purity, and is especially suitable for beer brewing that requires dilution or specific styles. | |||||||

| UV sterilization | Serves as a reliable microbial barrier to ensure the microbial safety of raw material water. | |||||||

III.Purification Goal

It is not about pursuing absolute purity, but targeted treatment — removing harmful impurities such as chlorine, chloramine, microorganisms, excessive heavy metals and organic substances, while regulating the types and concentrations of beneficial minerals to adapt to specific brewing processes and product styles.

IV.Key Principle

It is necessary to fully understand the characteristics of the water source first, and then formulate a personalized purification strategy in combination with the brewing goals. This is an important foundation for brewing high-quality wine.

V.Here is a guideline for you to get a proper quotation

Tell us the raw water/source of water(tap water, well water, or sea water, etc)

Provide water analysis report(TDS , conductivity, or resistivity, etc)

Required production capacity( 5m³/H, 50m³/H,or 500m³/H, etc)

What's the pure water used for( industrial,Food and Beverage,or agriculture, etc )

RO Membrane Photo:

|

|

1000GPH RO Reverse Osmosis Systems For Purification Of Raw Water For Brewing Images |